Note

You can

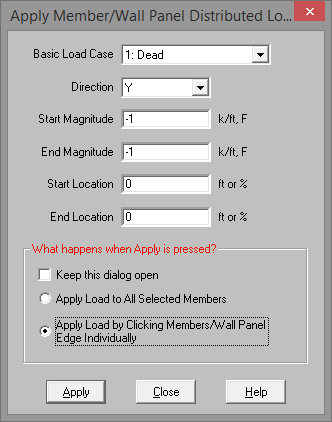

Make sure that you are careful to enter the correct Basic Load Case number that you want the loads assigned to.

To

Note

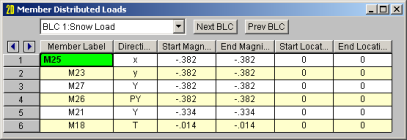

The Member Distributed Load Spreadsheet records the distributed loads

for the member elements and may be accessed by selecting ![]() Distributed Loads on the Spreadsheets menu,

Distributed Loads on the Spreadsheets menu,

The first column contains the Label of the element being loaded.

The Direction specified in the second column indicates which axes are to be used to define the load directions and whether or not the load is to be projected. Directions are discussed in the next section.

Start and End Magnitudes of the load must be specified. Start and End locations for the load need only be specified if the load is not across the full member length. If both locations are left as zero then the load will be applied across the full member length.

The Location columns contains the location of the load. The location

is the distance from the I

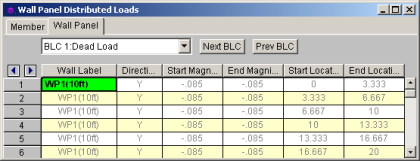

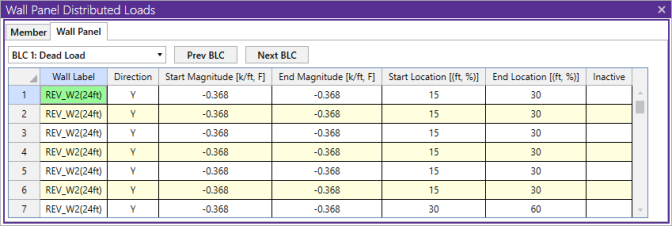

The Wall Panel Distributed Loads Spreadsheet records the distributed loads on your wall panels. Note that the loads are specific to the BLCs and that you can use the drop-down list to choose a different one. The columns in the spreadsheet are the same as the member distributed load spreadsheet.

The direction code indicates how the distributed load is to be applied. Following are the valid entries:

| Entry | Load Direction |

|---|---|

|

x or y |

Applied in the member’s local x or y-axis |

|

X or Y |

Applied in the global X or Y-axis |

|

T (or t) |

Thermal (temperature differential) load |

|

PX |

Projected load in the global X-axis direction |

|

PY |

Projected load in the global Y-axis direction |

|

SX |

Pressure load applied to projected surface of member in the global X-axis direction |

|

SY |

Pressure load applied to projected surface of member in the global Y-axis direction |

|

Sy |

Pressure load applied to projected surface of member in the local y-axis direction |

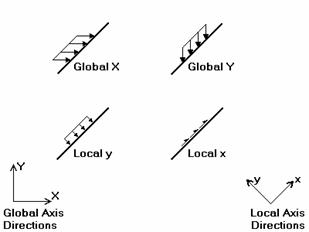

This diagram illustrates the difference between local (x, y, z) and global (X, Y, Z) direction loads:

In this diagram, the local y and global Y loads shown are both negative, while the local x and global X loads are positive. As can be seen, local direction loads line up with the element's local axis directions, so their direction relative to the rest of the model changes if the member/wall panel orientation changes. Global loads have the same direction regardless of the element's orientation.

A distributed load in the Mx direction will be applied to the member/wall panel

according to the right hand rule. Remember

that the positive local x-axis extends from the I

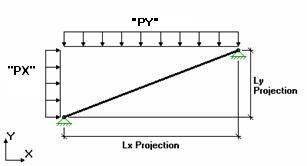

Keep in mind that global loads are applied without being modified for projection. For example, a full length Y direction load of 1 kip/foot applied to a 10 foot member inclined at 45 degrees generates a total force of 10 kips. Projected loads, on the other hand, are applied in the global directions but their actual magnitude is influenced by the member's orientation. The load is applied to the "projection" of the member perpendicular to the direction of the load. For example, a "PY" direction load is a projected load applied in the global Y direction. The actual magnitude of the load is the entered magnitudes reduced by the ratio L/Lx, where L is the member's full length and Lx is the member's projected length on the global Xaxis. See the following figure:

So the total load generated is equal to the input magnitudes applied along the projected length. This generated force is distributed along the full member length, so the applied magnitudes are reduced accordingly.

For additional advice on this topic, please see the RISA Tips & Tricks webpage at risa.com/post/support. Type in Search keywords: Projected Loads.

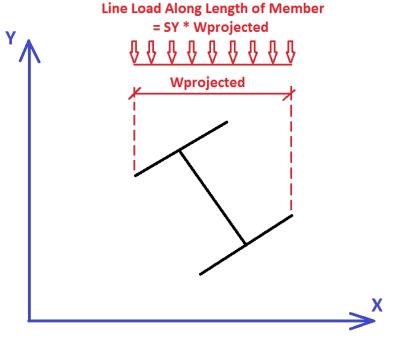

This is a load type that applies a pressure load to the face of the member in the direction specified. If a local axis direction is specified then the load will be applied to the strong/weak direction of the member regardless of the member orientation. If using the global coordinates then the program will take the projected face of the element in the direction in question and calculate the pressure area accordingly.

The program then takes this pressure multiplied by the width of the pressure area and creates a line load that is then applied to the member.

Note: